Process flow:

Entry plate -- roller brush chemical cleaning 1-- disk brush cleaning 1-- roller brush chemical cleaning 2-- disk brush cleaning 2-- fan drying 1.

Field of Application:

PBT-350MS on-line PCBA solvent based brush cleaner is an energy saving and environmental protection, batch cleaning of high-end cleaning machine, can complete automatic online cleaning, rinsing, drying functions.

• mainly used in military industry, aviation, aerospace, electronics, medical, new energy vehicles, vehicle electronic coating products and high precision products such as cleaning, washing, many varieties, large quantities of PCBA board can effectively clean the SMT/THT PCBA surface after welding residual rosin flux, water-soluble flux, no clean type flux/solder paste and other organic and inorganic contaminants;

• Cleaning solder paste on PCB board with poor printing, cleaning solder paste on scraper, etc.

Equipment features:

• Built-in filter device can realize solvent recycling and reduce solvent consumption;

• Visualization of the whole process: the cleaning room is equipped with a visual window to make the cleaning process clear at a glance;

• Automatic cleaning mode: the chain claw rail transmission, smooth and efficient, automatic cleaning, brushing;

• The most scientific scrub design: the combination of roller brush and disk brush, completely solve the cleaning blind area, the roller brush and disk can be disassembled;

• Body material: the whole body, liner, cleaning system is made of 304 stainless steel, acid, alkaline and other cleaning fluid resistance;

•ESD electrostatic requirements: less than 100V, and meet the requirements of ESDS20.20-2014; Working noise less than 80dB, solid barrier with emergency stop button, leakage protection function;

• Lower operating costs: lower equipment investment costs, localized service teams and adequate supply of spare parts;

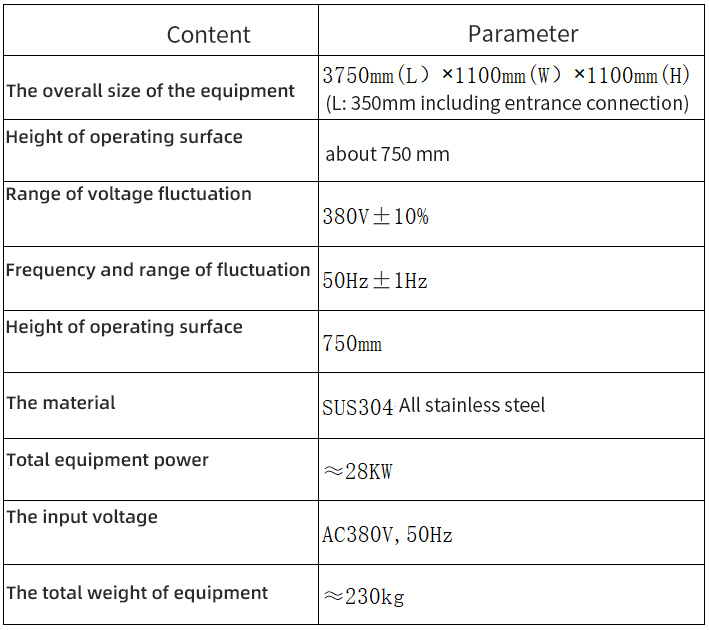

Technical parameters: